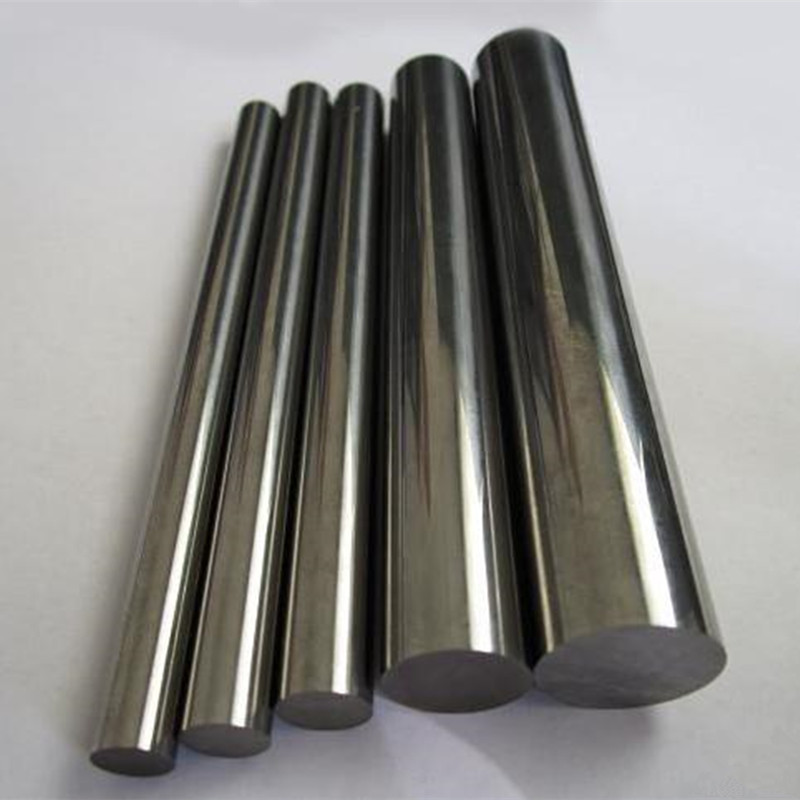

Tungsten Heavy Alloy Rod

Litlhaloso

Kereiti ea Tungsten Heavy Alloy:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Motlakase hanyenyane).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Nonmagnetic).

Tekano:16.8-18.8g/cm3.

Bokaholimo:E entsoe ka Mechini.

Tloaelo:ASTM B777.

Diameter:5.0mm - 80mm.

Bolelele:50-350 limilimithara.

Melemo ea Tungsten High Density Alloy

Boima bo phahameng (ho fihla ho 65% botenya ho feta lead).

Lisebelisoa tse teteaneng li teng (Tungsten e hloekileng, Khauta, litšepe tsa sehlopha sa platinum) empa tšebeliso ea tsona e thibetsoe ke ho fumaneha, ho sebetsa le litšenyehelo.

Ho fana ka boima moo sebaka sa bophahamo se fokolang.

Boima bo tebileng bo bohlokoa moo ho hlokehang ho nepahala ha boima.

Ho beha boima ba 'mele maemong ao ho phalla ha moea ho nang le tšusumetso e kholo.

Thermal Properties ea Tungsten Heavy Alloys

Mocheso o phahameng o nolofatsang.

Mocheso o fokolang oa mocheso le coefficient e tlase ea ho atolosa e fana ka boitsebiso bo hanyetsanang le mokhathala o chesang.

Ho hanyetsa khoholeho e ntle ea soldering ho aluminium e qhibilihisitsoeng.E matla ka mocheso o phahameng o nang le botsitso bo phahameng ba mocheso.

Tungsten High Density Alloy Mechanical Properties

● High Young's modulus ea elasticity.Ha e qhekelle ha e na le matla a bohlokoa, ho fapana le lead.

● Ho sa tsotellehe matla a tsona, li lula li le lerootho ebile li sa khone ho petsoha.

● Mefuta e thata ea li-alloys ka tloaelo ke 20-35 Hardness HRC.

Alloy e thehiloeng ho Tungsten e Phahameng ka ho Fetisisa

| Mofuta oa Alloy(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Balance Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| MIL-T-21014 | Sehlopha sa 1 | Sehlopha sa 1 | Sehlopha sa 1 | - | - | Sehlopha sa 3 | Sehlopha sa 3 | Sehlopha sa 4 |

| SAE-AMS-T-21014 | Sehlopha sa 1 | Sehlopha sa 1 | Sehlopha sa 2 | - | - | Sehlopha sa 3 | Sehlopha sa 3 | Sehlopha sa 4 |

| AMS 7725 C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 | Sehlopha sa 1 | Sehlopha sa 1 | Sehlopha sa 2 | - | - | Sehlopha sa 3 | Sehlopha sa 3 | Sehlopha sa 4 |

| Tekano e Tloaelehileng(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Tekano e Tloaelehileng(lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| RC e Tloaelehileng | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ultimate Tensile Matla Min(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Offset Yield Matla Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Bonyane % Elongation(1"bolelele ba gage) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Proportional Elastic Limit(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Modulus ea Elasticity(x106psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Thermal Conductivity(Diyuniti tsa CGS) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Motlakase Conductivity(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetic | No | Hanyane | Hanyane | Hanyane | Hanyane | No | Hanyane | Hanyane |