Tungsten Copper WCu Heat Sink

Tlhaloso

Lisebelisoa tsa ho paka tsa elektroniki tsa Tungsten li na le thepa e tlase ea ho hola ea tungsten le thepa e phahameng ea mocheso oa koporo. Ntho ea bohlokoa ka ho khetheha ke hore coefficient ea eona ea katoloso ea mocheso le conductivity ea mocheso e ka etsoa ka ho lokisa sebopeho sa thepa e tlisitseng boiketlo bo boholo.

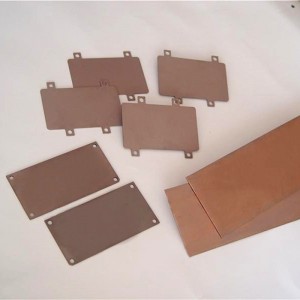

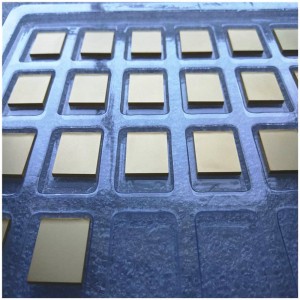

FOTMA e sebelisa lisebelisoa tse tala tsa boleng bo holimo le tsa boleng bo phahameng, 'me e fumana lisebelisoa tsa ho paka tsa elektronike tsa WCu le lisebelisoa tsa ho teba ha mocheso ka ts'ebetso e babatsehang ka mor'a ho hatella, ho kenya mocheso o phahameng le ho kenella.

Melemo ea Tungsten Copper (WCu) Electronic Packaging Materials

1. Thepa ea elektronike ea koporo ea tungsten e na le coefficient ea ho atolosa mocheso o feto-fetohang, o ka kopanngoa le li-substrates tse fapaneng (tse kang: tšepe e sa hloekang, alloy valve, silicon, gallium arsenide, gallium nitride, aluminium oxide, joalo-joalo);

2. Ha ho lisebelisoa tsa ts'ebetso ea sintering tse kenyelletsoeng ho boloka conductivity e ntle ea mocheso;

3. Porosity e tlase le ho tiea ha moea hantle;

4. Ho laola boholo bo botle, ho qeta holimo le ho batalla.

5. Fana ka lakane, likarolo tse entsoeng, hape li ka finyella litlhoko tsa electroplating.

Thepa ea Copper Tungsten Heat Sink

| Kereiti ea lintho tse bonahalang | Tungsten Content Wt% | Boima ba g/cm3 | Katoloso ea Mocheso × 10-6CTE (20℃) | Thermal Conductivity W/ (M·K) |

| 90WCU | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCU | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCU | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCU | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Ho sebelisoa ha Tungsten Copper Heat Sinks

Lisebelisoa tse loketseng ho paka ka lisebelisoa tsa matla a phahameng, tse kang li-substrates, li-electrode tse tlaase, joalo-joalo; liforeimi tse etellang pele tse sebetsang hantle; liboto tsa taolo ea mocheso le li-radiator bakeng sa lisebelisoa tsa sesole le tsa sechaba tse laolang mocheso.