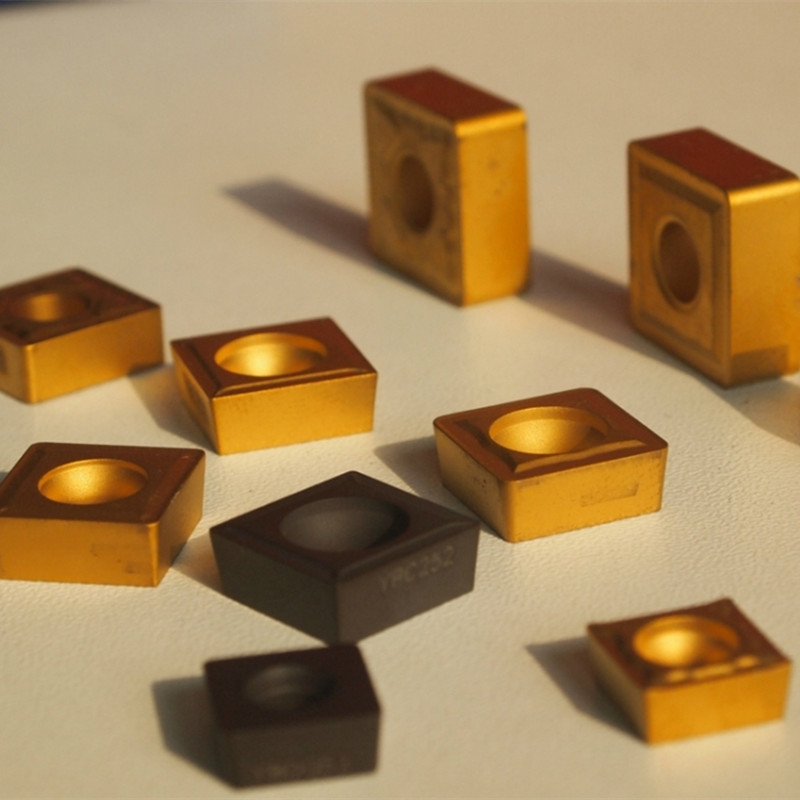

Carbide CNC Indexable Insets

Lisebelisoa tse kentsoeng tsa carbide CNC li entsoe haholo ka carbide e tiileng joalo ka 'mele oa motheo,' me li sebetsoa ka mekhoa e mengata ea tlhahiso.

Carbide e entsoeng ka samente, eo hape e tsejoang e le tungsten steel, e entsoe ka tungsten carbide + cobalt phofo ea boleng bo holimo ka mor'a ho tsoakoa ka foromo le sintering.E na le boima bo phahameng, matla a phahameng, khanyetso e phahameng ea ho apara le modulus e phahameng ea elastic.Ke ea indasteri ea phofo ea metallurgy..Joaloka meno a indasteri ea sejoale-joale, lisebelisoa tsa ho seha li-carbide li phetha karolo ea bohlokoa ho nts'etsopele ea indasteri ea tlhahiso.

Carbide e entsoeng ka samente e na le letoto la lintho tse ntle tse kang boima bo phahameng, ho hanyetsa ho roala, matla a matle le ho tiea, ho hanyetsa mocheso le ho hanyetsa ha kutu, haholo-holo boima ba eona bo phahameng le ho hanyetsa ho apara, tse lulang li sa fetohe esita le mocheso oa 500 ° C, o ntse o e-na le eona. boima bo phahameng ho 1000 ℃.

Kopo:

Li-Carbide Insets li sebelisoa haholo bakeng sa ho seha, ho sila, ho reteleha, ho etsa mapolanka, ho korotla joalo-joalo.

E entsoe ke lisebelisoa tsa boleng bo holimo tsa tungsten carbide.Phekolo ea boleng bo holimo le ho roala ka TiN.

Khamphani ea rona e na le mohala o tsoetseng pele oa tlhahiso bakeng sa ho etsa li-dies and hlobo le mohala oa tlhahiso bakeng sa lihlahisoa tsa carbide tse entsoeng ka mochini.Re ka boela ra fana ka lihlahisoa tse entsoeng ka mokhoa o ikhethileng oa litlhaloso tse fapaneng ho latela litlhoko tsa bareki ba rona.

Li-Grades tsa Cemented Carbide tsa CNC Indexable Insets.

| Kereiti | Lisebelisoa |

| C2 e sa koahetsoeng | Ho hanyetsa ho apara ho phahameng le matla a phahameng;machining chilled cast iron and refractory iron, finishing of normal cast iron. |

| C5 e sa koahetsoeng | E babatsehang ka matla, ho hanyetsa tšusumetso le ho hanyetsa mocheso oa mocheso;Phetoho e mahlahahlaha, moralo o thata le moralo oa semi oa tšepe ea Carbon le tšepe ea alloy. |

| ZK10UF | Alloy e nang le grained e ntle, ho hanyetsa ho apara hantle le matla a phahameng.Semi-finishing le ho qeta tšepe e entsoeng ka tšepe le litšepe tse se nang ferrous.Ke thepa e ikhethang ea ho etsa lisebelisoa tse tiileng tsa carbide bakeng sa holing. |

| ZK30UF | Mokhahlelo o motle oa lijo-thollo.E babatsehang ho apara ho hanyetsa, matla a phahameng le ho hanyetsa tšusumetso.Ho sebetsa ka litšepe tse entsoeng ka tšepe, litšepe tse se nang ferrous le lisebelisoa tse se nang tšepe.Ke thepa e ikhethang ea lisebelisoa tse tiileng tsa carbide bakeng sa holing. |

| ZP25 | E ntle ka ho hanyetsa ho apara le ho tiea;Phetoho e thata, ho sila, ho cheka le ho cheka botebo ba tšepe ea carbon, tšepe e entsoeng ka tšepe, tšepe ea manganese le tšepe ea motsoako. |

| ZP35 | Sehlopha se feto-fetohang, se nang le boima bo bofubelu bo phahameng, matla le ho hanyetsa tšusumetso le ho sisinyeha ha mocheso.Seha se thata le se matla sa tšepe le tšepe e entsoeng ka tšepe. |

| Tlhahiso: Re rata ho khothaletsa sehlopha se loketseng ho latela lisebelisoa tsa hau tsa mochini. | |