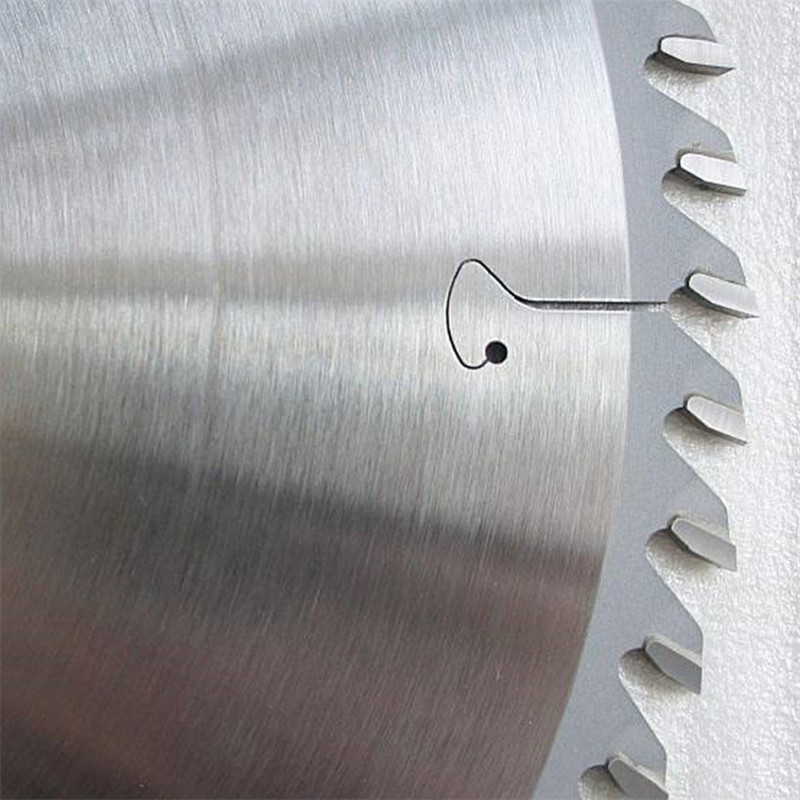

Tungsten Carbide e entsoeng ka samente e entsoeng ka Saw Blade

Li-saha tsa Carbide li sebelisetsoa ho rema lehong, tšepe kapa lisebelisoa tse ling tse thata.Li ka sebetsoa ka letsoho kapa tsa tsamaisoa.Li-blades tsa rona tsa sakha li sebelisetsoa ho phekola holim'a tšepe e entsoeng ka tšepe, litšepe tse se nang ferrous le li-alloys, hammoho le tšepe e thata, carbide rough turning, roughing le ho siloa ka mokhoa o nepahetseng oa thepa e se nang tšepe.

Re ka fana ka limaraka tse ntlafalitsoeng tsa carbide ea mapolanka le meralo ea profil ea meno ha re e kopa, hammoho le ho eletsoa ka lehare la sakha le loketseng ka ho fetisisa bakeng sa tšebeliso ea moreki.

Mabapi le li-blade tsa carbide tungsten carbide saw blades tsa mapolanka a li-circular saw, mefuta ea rona ea limaraka e akaretsa lits'ebetso tse ngata.Sehlopha sa K10 se na le ts'ebetso e matla ho lehong le bonolo le le thata.K20 e na le khanyetso e ntle ea ho roala le ho tiea 'me e loketse ho sebetsa ha lehong kapa liphalete hammoho le ho lokisa lifate.Bakeng sa lisebelisoa tsa ho itšeha ka tšepe, re boetse re fana ka limaraka tse ling.Likarolo tse ling tsa likopo tsa litsebi li fumaneha ka taelo e khethehileng.

Lenane la Kereiti ea Tungsten Carbide Blades

| Kereiti | Botenya | Ho thatafala | Matla | Lisebelisoa | Boemo ba ISO |

| YG6X | 14.8-15 | 91.7-93 | 1600 | Ho hanyetsa ho apara ho phahameng le matla a phahameng; | K10(ANSI C-2) |

| YT5 | 12.85-13.05 | 89.5-91 | 1700 | E babatsehang ka matla, ho hanyetsa tšusumetso | P30(ANSI:C-5) |

| YT15 | 11.2-11.4 | 92-93 | 1350 | Ho hanyetsa ho apara hantle, ka mokhoa o tloaelehileng | P10 |

| YT14 | 11.3-11.6 | 91.3-92.3 | 1450 | E phahameng ka ho hanyetsa tšusumetso le matla; | P20-P30 |

| YT535 | 12.6-12.8 | 90-91,5 | 1760 | Khanyetso e phahameng ea ho apara le boima bo bofubelu, | P30 |

| ZP25 | 12.5-12.7 | 91.4-92.3 | 1750 | E ntle ka ho hanyetsa ho apara le ho tiea; | P20-P30 |

| ZP35 | 12.6-12.8 | 90.5-91,5 | 1770 | Kereiti e feto-fetohang, boima bo bofubelu bo holimo, | P30-P40 |

| YG6 | 14.8-15 | 90-92 | 1650 | Ho hanyetsa ho apara hantle, ho hanyetsa ho | K15-K20 |

| YW1 | 13.25-13.5 | 92-93.2 | 1420 | Kereiti e feto-fetohang, e ntle ka boima bo bofubelu, | M10/P10 |

| YW2 | 13.15-13.35 | 91.3-92.3 | 1600 | Ho hanyetsa ho apara hantle le matla a phahameng, | M20/P20-30 |

| YW2A | 12.85-13.05 | 91.5-92,5 | 1670 | Bofubelu bo botle bo thata, bo khonang ho mamella | M15/P15 |

| ZM15 | 13.8-14.0 | 91-92.2 | 1720 | Bofubelu bo botle bo botle, matla a phahameng a sebelisoang, | M15 |

| ZM30 | 13.5-13.7 | 90-91,5 | 1890 | Matla a phahameng a sebelisoang, a khonang ho hanyetsa | M30 |

| ZK10UF | 14.75-14.95 | 92.6-93.6 | 1690 | Alloy e nang le grained e ntle, ho hanyetsa ho apara hantle | K10-K15 |

| ZK30UF | 14.3-14.55 | 91.2-92.2 | 2180 | Mokhahlelo o motle oa lijo-thollo.E ntle ka ho fetisisa ea ho apara, | K30 |

| Tlhokomeliso: Matsatsi a boletsoeng ke maemo a tloaelehileng, litlhaloso tsa 'nete tsa lihlahisoa li betere haholo | |||||

| Tlhahiso: Re rata ho khothaletsa sehlopha se loketseng ho latela lisebelisoa tsa hau tsa mochini. | |||||