Lipheo tsa Tungsten Sputtering

Lipheo tsa Tungsten Sputtering

Lipheo tsa Tungsten sputtering li bapala karolo ea bohlokoa lits'ebetsong tse fapaneng tsa theknoloji ea sejoale-joale. Lipheo tsena ke karolo ea bohlokoa ea ts'ebetso ea sputtering, e sebelisoang haholo liindastering tse kang tsa elektroniki, li-semiconductors le tsa optics.

Thepa ea tungsten e etsa hore e be khetho e nepahetseng bakeng sa liphofu tsa sputtering. Tungsten e tsejoa ka sebaka sa eona se phahameng sa ho qhibiliha, ho tsamaisa mocheso o motle haholo, le khatello e tlase ea mouoane. Litšobotsi tsena li e lumella ho mamella mocheso o phahameng le ho phatloha ha liphatsa tse matla nakong ea ts'ebetso ea sputtering ntle le ho senyeha ho hoholo.

Indastering ea lisebelisoa tsa elektroniki, sepheo sa tungsten sputtering se sebelisoa ho beha lifilimi tse tšesaane ho li-substrates bakeng sa ho etsa lipotoloho tse kopaneng le lisebelisoa tse nyane tsa elektroniki. Taolo e nepahetseng ea ts'ebetso ea sputtering e netefatsa ho ts'oana le boleng ba lifilimi tse behiloeng, tse bohlokoa bakeng sa ts'ebetso le ts'epahalo ea likarolo tsa elektronike.

Ka mohlala, ha ho etsoa lipontšo tsa phanele e bataletseng, lifilimi tse tšesaane tsa tungsten tse kentsoeng ho sebelisoa liphofu tsa sputtering li kenya letsoho ho tsamaiseng le tšebetsong ea liphanele tsa ponts'o.

Lefapheng la semiconductor, tungsten e sebelisoa bakeng sa ho theha likhokahano le likarolo tsa lithibelo. Bokhoni ba ho kenya lifilimi tsa tungsten tse tšesaane le tse lumellanang li thusa ho fokotsa khatello ea motlakase le ho ntlafatsa ts'ebetso ea sesebelisoa ka kakaretso.

Lisebelisoa tsa Optical li boetse li rua molemo ho lipheo tsa tungsten sputtering. Liaparo tsa tungsten li ka ntlafatsa ho bonahatsa le ho tšoarella ha likarolo tsa optical, tse kang liipone le lilense.

Boleng le bohloeki ba lipheo tsa tungsten sputtering ke tsa bohlokoa ka ho fetisisa. Esita le litšila tse nyenyane li ka ama thepa le ts'ebetso ea lifilimi tse behiloeng. Baetsi ba sebelisa mehato e tiileng ea taolo ea boleng ho netefatsa hore lipehelo li fihlela litlhoko tse boima tsa lits'ebetso tse fapaneng.

Lipheo tsa Tungsten sputtering li bohlokoa haholo ho nts'etsopele ea mahlale a sejoale-joale, ho thusa ho theoa lifilimi tse tšesaane tsa boleng bo holimo tse tsamaisang nts'etsopele ea lisebelisoa tsa elektroniki, li-semiconductors le optics. Ntlafatso ea bona e tsoelang pele le boqapi ntle le pelaelo li tla bapala karolo ea bohlokoa ho bopeng bokamoso ba liindasteri tsena.

Mefuta e fapaneng ea litebello tsa Tungsten Sputtering le Ts'ebeliso ea tsona

Ho na le mefuta e 'maloa ea liphofu tsa tungsten, e' ngoe le e 'ngoe e na le litšobotsi le ts'ebeliso ea eona.

Lipheo tse Hloekileng tsa Tungsten tsa Sputtering: Tsena li entsoe ka tungsten e hloekileng 'me e atisa ho sebelisoa lits'ebetsong moo sebaka se phahameng sa ho qhibiliha, conductivity e ntle ea mocheso, le khatello e tlaase ea mouoane e leng tsa bohlokoa. Hangata ba sebelisoa indastering ea semiconductor bakeng sa ho kenya lifilimi tsa tungsten bakeng sa likhokahano le likarolo tsa lithibelo. Mohlala, ha ho etsoa li-microprocessors, sputtering e hloekileng ea tungsten e thusa ho theha likhokahano tse tšepahalang tsa motlakase.

Alloyed Tungsten Sputtering Targets: Lipehelo tsena li na le tungsten e kopantsoeng le likarolo tse ling tse kang nickel, cobalt, kapa chromium. Lipheo tsa alloyed tungsten li sebelisoa ha ho hlokahala thepa e khethehileng. Mohlala ke indastering ea sepakapaka, moo sepheo sa alloyed tungsten sputtering se ka sebelisoang ho etsa liphahlo holim'a likarolo tsa turbine bakeng sa matla a matla a ho hanyetsa mocheso le ho se mamelle.

Lipheo tsa Tungsten Oxide Sputtering: Tsena li sebelisoa lits'ebetsong moo ho hlokahalang lifilimi tsa oxide. Ba fumana ts'ebeliso ho hlahiseng li-oxide tsa transparent conductive bakeng sa lipontšo tsa sekirini sa touchscreen le lisele tsa letsatsi. The oxide layer e thusa ho ntlafatsa conductivity ea motlakase le thepa ea optical ea sehlahisoa sa ho qetela.

Lipheo tse kopaneng tsa Tungsten Sputtering: Tsena li na le tungsten e kopantsoeng le lisebelisoa tse ling ka sebopeho sa motsoako. Li sebelisoa maemong ao ho hlokahalang motsoako oa thepa ho tsoa ho likarolo tseo ka bobeli. Ka mohlala, ha ho roaloa lisebelisoa tsa bongaka, sepheo sa tungsten se kopantsoeng se ka sebelisoa ho etsa lesela le lumellanang le biocompatible le le tšoarellang.

Khetho ea mofuta oa sepheo sa tungsten sputtering e itšetlehile ka litlhoko tse khethehileng tsa kopo, ho kenyelletsa le thepa ea filimi e lakatsehang, thepa ea substrate, le maemo a ho sebetsa.

Sesebelisoa sa Target sa Tungsten

E sebelisoa haholo lipontšong tsa liphanele tse bataletseng, lisele tsa letsatsi, li-circuits tse kopaneng, likhalase tsa likoloi, li-microelectronics, mohopolo, li-tubes tsa X-ray, lisebelisoa tsa bongaka, lisebelisoa tse qhibilihang le lihlahisoa tse ling.

Boholo ba lipheo tsa Tungsten:

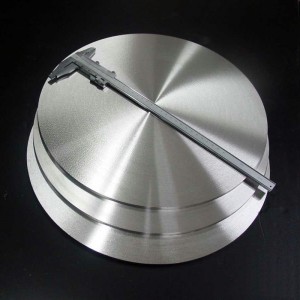

Sepheo sa disc:

Boima: 10mm ho 360mm

Botenya: 1mm ho 10mm

Morero o hlophisitsoeng

Bophara: 20mm ho 600mm

Bolelele: 20mm ho 2000mm

Botenya: 1mm ho 10mm

Sepheo sa rotary

Ka ntle bophara: 20mm ho 400mm

Botenya ba lebota: 1mm ho isa ho 30mm

Bolelele: 100mm ho 3000mm

Litlhaloso tsa sepheo sa Tungsten Sputtering:

Ponahalo: silevera e tšoeu ea tšepe e khanyang

Bohloeki: W≥99.95%

Boima: ho feta 19.1g/cm3

Boemo ba phepelo: Ho belisoa ha sefahleho, ho sebetsa ka mochini oa CNC

Tekanyetso ea boleng: ASTM B760-86, GB 3875-83