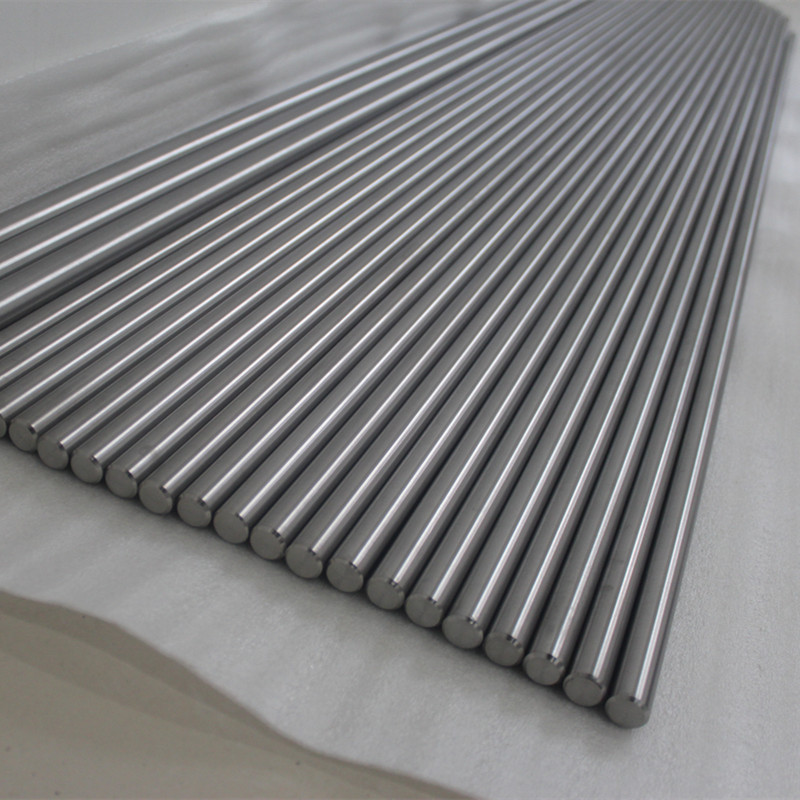

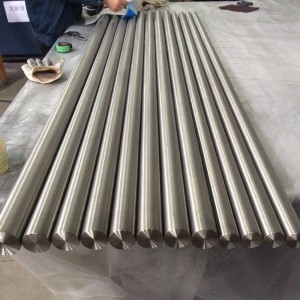

Sebaka se hloekileng sa Titanium Rod Titanium Alloy Bar

Tlhaloso

Titanium rod ke thepa e tala e sebelisoang ho etsa motsoako oa titanium le tšepe ea titanium. E na le litšobotsi tse fokolang haholo, matla a phahameng le khanyetso e ntle ea kutu. Indastering ea sepakapaka, molamu oa titanium o sebelisoa haholo ha ho etsoa likarolo tsa sebopeho sa lifofane le li-nozzles tsa rocket; indastering ea lik'hemik'hale, e sebelisoa e le sesebelisoa sa catalyst le sesebelisoa sa tlhoekiso bakeng sa li-electrolyte; indastering ea mechine, e ka sebelisoa e le mocheso oa mocheso le thepa ea condenser.

Lefapheng la metallurgical, titanium rod/bar e sebelisoa haholo-holo ho hlahisa tšepe e sa tšoaneng e hloekileng, tšepe e sa hloekang, tšepe e sa keneleng mocheso le tšepe e khethehileng ea alloy. Ntle le moo, e boetse e sebelisoa ha ho etsoa mahakoe a maiketsetso le likristale tsa maiketsetso tsa rutile zircon, lishiti tsa ceramic tsa piezoelectric bakeng sa indasteri ea elektroniki, le mehala e nepahetseng ea libopeho tse fapaneng.

Litlhaloso tsa Bar ea Titanium e hloekileng / Titanium Alloy Bar

Sehlopha sa Titanium Alloy:Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6,Ti-6al-7Nb.

Kreiti ea Titanium e hloekileng ea khoebo:Gr.3, Gr.4 khoebo e hloekileng.

Sebaka sa Diameter:Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, joalo-joalo.

Maemo a Mamello:ISO 286

Tloaelo:ASTM F67, ASTM F136, ISO 5832.

Bolelele bo teng:2.5 m ~ 3 m (98.4 ~ 118.1"), kapa e etselitsoeng motho.

Ho otloloha:e phethahetseng bakeng sa mochini oa CNC.

Lithupa tsohle tsa Titanium le Titanium Alloy li ka fanoa ka bophara bo ikhethileng kapa bolelele, ho lekana litlhoko tsa bareki.

Likarolo tsa lithupa tsa titanium alloy:Elasticity e ntle haholo, matla a phahameng le homogeneous microstructure.

Titanium Grade e Fumaneha

| ASTM B265 | GB/T 3620.1 | JIS H4600 | Litaba tsa mantlha (wt%) | ||||||

| N, Max | C, Max | H, Max | Fe, Max | O, Max | Ba bang | ||||

| HloekilengTitanium | Gr.1 | TA1 | Sehlopha sa 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Sehlopha sa 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Sehlopha sa 3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA4 | Sehlopha sa 4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | - | |

| TitaniumAlloy | Gr.5 | TC4Ti-6Al-4V | Sehlopha sa 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5,5-6,75;V:3.5-4.5 |

| Sehlopha sa 7 | TA9 | Sehlopha sa 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Pd: 0.12-0.25 | |

| Gr.11 | TA9-1 | Sehlopha sa 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Pd: 0.12-0.25 | |

| Gr.23 | TC4 ELI | Sehlopha sa 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5,5-6,5;V:3.5-4.5 | |