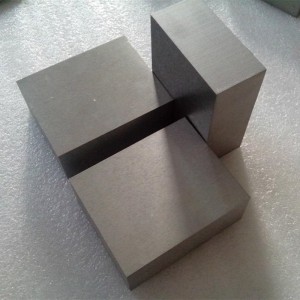

Silver Tungsten Alloy

Silver tungsten alloy ke motsoako o sa tloaelehang oa litšepe tse peli tse makatsang, silevera le tungsten, e fanang ka thepa le lits'ebetso tse ikhethang.

Alloy e kopanya conductivity e ntle ea motlakase ea silevera le ntlha e phahameng ea ho qhibiliha, ho thatafala, le ho hanyetsa ho apara ha tungsten. Sena se etsa hore e tšoanelehe haholo bakeng sa lits'ebetso tse fapaneng tse batloang masimong a motlakase le a mechini.

Indastering ea motlakase, alloy ea silevera ea tungsten e sebelisoa ho likhokahano tsa motlakase le li-switches. Bokhoni ba eona ba ho mamella mocheso o phahameng le arcing bo etsa hore e tšepahale likarolong tsena tsa bohlokoa. Ka mohlala, lits'ebetsong tsa motlakase tse matla haholo, moo phallo ea hona joale e leng ea bohlokoa le kotsi ea ho chesa haholo, tšebeliso ea alloy ea silevera ea tungsten e etsa bonnete ba hore ts'ebetso e sebetsa hantle le e sireletsehileng.

Sebakeng sa mechini, e fumana ts'ebeliso ea lisebelisoa mme e shoa ka lebaka la ho thatafala ha eona le ho tšoarella ha eona. Likarolo tse entsoeng ka alloy ena li ka mamella khatello e matla ea mochini le ho roala ho hoholo, ho lelefatsa bophelo ba tsona le ho ntlafatsa ts'ebetso.

Tlhahiso ea alloy ea silevera ea tungsten hangata e kenyelletsa mekhoa e rarahaneng ho finyella sebopeho se lakatsehang le microstructure. Sena se tiisa tekano e nepahetseng ea thepa bakeng sa lits'ebetso tse ikhethileng.

Lipatlisiso le nts'etsopele lefapheng la li-alloys tsa tungsten tsa silevera li ntse li tsoela pele ho fetoha, ho bula menyetla e mecha le ntlafatso. Bo-rasaense le baenjiniere ba lula ba hlahloba mekhoa ea ho ntlafatsa thepa ea eona le ho holisa mefuta ea eona ea ts'ebeliso.

Qetellong, alloy ea silevera ea tungsten e eme e le bopaki ba bohlale ba motho ho saense ea thepa, e fanang ka tharollo mathateng a mang a thata ka ho fetisisa a boenjiniere le a theknoloji. Motsoako oa eona o ikhethang oa thepa o etsa hore e be thepa ea bohlokoa haholo indastering e fapaneng, e bopang lefatše la sejoale-joale ka boteng ba lona le bokhoni ba lona.

Ho etsoa ha silevera ea tungsten alloy:

Metallurgy ea phofo:

Ena ke mokhoa o tloaelehileng. Li-powders tse ntle tsa silevera le tungsten li kopantsoe ka tekanyo e lakatsehang. Motsoako o ntan'o kopanngoa tlas'a khatello e phahameng ho theha compact e tala. Ka mor'a moo compact ena e sintered ka mocheso o phahameng ho kopanya likaroloana le ho etsa motsoako o tiileng. Ka mohlala, maemong a mang, phofo e ka 'na ea siloa hammoho pele ho etsa bonnete ba hore motsoako oa homogeneous.

Kemiso ea Mouoane oa lik'hemik'hale (CVD):

Ka mokhoa ona, li-precursors tsa gaseous tse nang le silevera le tungsten li kenngoa ka kamoreng ea karabelo. Tlas'a maemo a itseng a mocheso le khatello, li-precursors li itšoara le ho beha holim'a substrate ho etsa lera la alloy. Mokhoa ona o lumella ho laola ka nepo sebopeho sa alloy le microstructure.

Electroplating:

Silver tungsten alloy e ka boela ea etsoa ka electroplating. Substrate ea tungsten e qoelisoa ka har'a electrolyte e nang le li-ion tsa silevera. Ka ho sebelisa motlakase, silevera e kenngoa holim'a tungsten, ho etsa lera la alloy. Ts'ebetso ena e ka fetoloa ho fihlela mefuta e fapaneng ea botenya le lipina tsa ho roala alloy.

Sinter-HIP (Hot Isostatic Pressing):

Motsoako oa phofo o qala ka sintered ebe o kenngoa tlas'a khatello e chesang ea isostatic. Sena se thusa ho felisa porosity le ho ntlafatsa sepakapaka le thepa ea mechine ea motsoako o entsoeng.

Khetho ea mokhoa oa ho etsa masela e itšetlehile ka lintlha tse sa tšoaneng tse kang thepa e lakatsehang ea motsoako oa ho qetela, sebōpeho le boholo ba karolo e lokelang ho hlahisoa, le tekanyo ea tlhahiso. Mokhoa o mong le o mong o na le melemo le mefokolo ea ona, 'me hangata, motsoako oa mekhoa ena o ka sebelisoa ho fihlela litholoana tse ntle.

Silver tungsten alloy e na le lits'ebetso tse 'maloa tse ikhethileng ka lebaka la thepa ea eona e ikhethang:

Mabitso a Motlakase:

● Ka li-circuit breakers tse nang le matla a phahameng, moo e khonang ho sebetsana le maqhubu a maholo le ho fetoha khafetsa ntle le ho senyeha ho hoholo kapa ho senyeha.

● Ho li-relay le li-contact bakeng sa litsamaiso tsa taolo ea indasteri, ho fana ka khokahanyo e tšepahalang ea motlakase le bophelo bo bolelele ba tšebeletso.

Li-electrode:

● Bakeng sa machining a ho ntša motlakase (EDM), moo conductivity ea eona e phahameng le ho hanyetsa ho apara ho netefatsa ho tlosoa ha thepa e nepahetseng le e sebetsang hantle.

● Ka li-electrode tsa welding tsa arc, tse fanang ka mocheso o motle oa ho senya le ho tšoarella.

Likarolo tsa Aerospace:

● Likarolong tsa lienjine tsa lifofane le litsamaiso tsa sepaka-paka tse hlokang thepa e hanyetsanang le mocheso o phahameng le matla a mochine.

Tsamaiso ea Mocheso:

● Ha mocheso o teba ka har'a lisebelisoa tsa elektroniki, ho tsamaisa mocheso ka katleho le ho o ntša.

Ho sebetsa le ho shoa:

● Bakeng sa ts'ebetso ea setempe le ho theha, haholo-holo lits'ebetsong tseo ho tsona ho leng bohlokoa haholo ho thatafala le ho hanyetsa ho apara.

Mabenyane:

● Ka lebaka la ponahalo ea eona e khahlehang le e tšoarellang, e ka sebelisoa ha ho etsoa likotoana tse khethehileng tsa mabenyane.

Mohlala, indastering ea likoloi, likhokahano tsa alloy tsa silevera tsa tungsten li sebelisoa ho li-motor tse qalang ho netefatsa ho qaleha ho tšepahalang ha enjene tlasa maemo a fapaneng. Lefapheng la likhokahano tsa mehala, e sebelisoa li-switches tse phahameng haholo ho boloka botsitso ba matšoao le ho fokotsa tahlehelo ea matšoao.

Silver Tungsten Alloy Properties

| Nomoro ea khoutu. | Sebopeho sa Lik'hemik'hale % | Thepa ea mechine | ||||||

| Ag | Ho se hloeke≤ | W | Botenya (g/cm3 ) ≥ | Ho thatafala HB ≥ | RES (μΩ·cm) ≤ | Boikhantšo IACS/ % ≥ | TRS/ Mpa ≥ | |

| AgW(30) | 70±1.5 | 0.5 | Ho leka-lekanya | 11.75 | 75 | 2.3 | 75 | |

| AgW(40) | 60±1.5 | 0.5 | Ho leka-lekanya | 12.40 | 85 | 2.6 | 66 | |

| AgW(50) | 50±1.5 | 0.5 | Ho leka-lekanya | 13.15 | 105 | 3.0 | 57 | |

| AgW(55) | 45±2.0 | 0.5 | Ho leka-lekanya | 13.55 | 115 | 3.2 | 54 | |

| AgW(60) | 40±2.0 | 0.5 | Ho leka-lekanya | 14.00 | 125 | 3.4 | 51 | |

| AgW(65) | 35±2.0 | 0.5 | Ho leka-lekanya | 14.50 | 135 | 3.6 | 48 | |

| AgW(70) | 30±2.0 | 0.5 | Ho leka-lekanya | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±2.0 | 0.5 | Ho leka-lekanya | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±2.0 | 0.5 | Ho leka-lekanya | 16.10 | 180 | 4.6 | 37 | 726 |